For investors and bowling center operators, choosing the right lanes is one of the most important decisions. Unlike other equipment, lanes form the foundation of every game and directly impact player satisfaction. A reliable Bowling Lanes Supplier helps buyers evaluate and compare options to ensure long-term value. This guide outlines the key factors buyers should consider before making a final purchase.

🪵 1. Material Selection

The first step in comparing lanes is assessing the materials used. Buyers should look for suppliers that offer:

Hardwoods like maple and pine for durability and play consistency

Synthetic laminates for moisture resistance and lower maintenance

Protective coatings to extend surface life

Eco-friendly alternatives to meet global sustainability standards

Working with a professional Bowling Lanes Manufacturer ensures these materials meet international benchmarks.

🏗️ 2. Construction Standards

How lanes are built affects both performance and longevity. Buyers should evaluate whether factories use:

CNC machining for precise dimensions

Laser alignment technology to ensure accurate installation

Moisture and temperature controls during production

Standardized substructures for heavy traffic durability

Consistent construction means fewer maintenance issues and more reliable play over time.

⚙️ 3. Performance and Playability

Performance is not only about looks—it’s about the experience on the lanes. A trusted Bowling Lanes Supplier provides lanes with:

Smooth surfaces for consistent ball roll

Finishes that support proper oil patterns

Noise-reducing underlayers for comfort

Reinforced bases to withstand high daily usage

👉 For related systems that enhance performance, explore our Bowling Ball Return Manufacturer page.

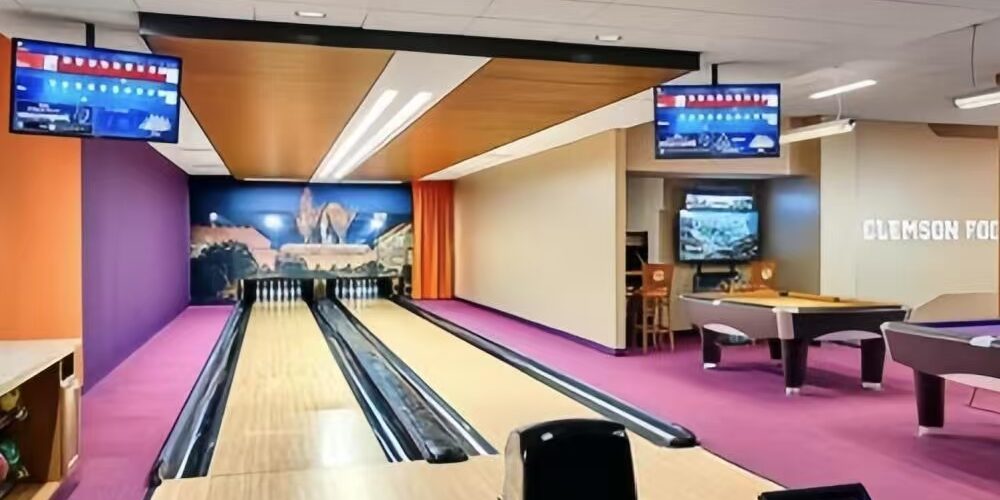

🎨 4. Customization Opportunities

Long-term success often depends on branding. Many buyers now prefer custom bowling lanes to reflect their unique identity. Options may include:

Branded logos printed directly onto the lanes

Custom lane colors and finishes

Adapted sizes for boutique or entertainment-focused venues

👉 For larger, coordinated supply needs, review our Bowling Equipment Wholesale section.

📦 5. Wholesale Supply and Logistics

For investors building or expanding multiple centers, wholesale supply is critical. Buyers should ask suppliers about:

Capacity for bulk orders

Export-compliant packaging to avoid transit damage

Clear documentation for customs clearance

Installation and after-sales support

Choosing a supplier with strong wholesale experience reduces risks and ensures smoother project execution.

🌍 6. Compliance and Certifications

Global buyers must confirm that suppliers comply with CE, ISO, or other certifications. This not only ensures lane safety and durability but also simplifies international shipping and import processes.

📈 Conclusion

Comparing bowling lanes for long-term use requires more than checking prices. Buyers should evaluate materials, construction, performance, customization, wholesale capabilities, and compliance. By working with a reliable Bowling Lanes Supplier, investors gain confidence that their lanes will deliver both durability and customer satisfaction.

Partnering with an experienced Bowling Lanes Manufacturer ensures long-term value, making the investment in bowling infrastructure both profitable and sustainable.